As a business owner or facility manager, you know that proper lighting is crucial for maintaining safety, efficiency, and productivity in your cold storage environments. But did you know that upgrading to specialized cold storage lighting solutions can completely transform your operations? From enhancing worker safety to reducing energy costs and improving product visibility, the right lighting can have a profound impact on your bottom line.

In this comprehensive guide, we’ll dive deep into the world of cold storage lighting, exploring its unique challenges, key benefits, and the latest trends and technologies shaping the industry. Whether you manage a small cold room or a large-scale refrigerated warehouse, you’ll come away with actionable insights and practical tips to optimize your lighting setup and take your business to the next level.

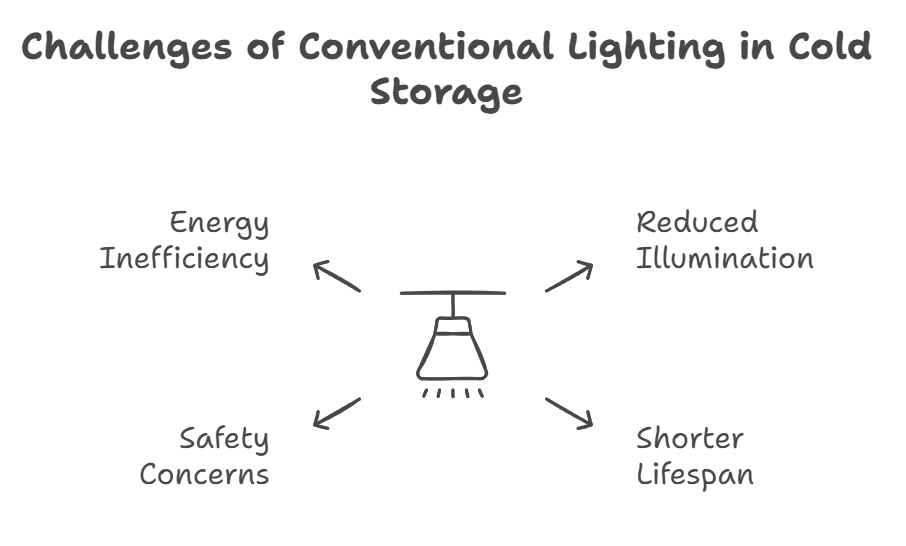

The Unique Challenges of Cold Storage Environments

Before we explore the benefits of specialized cold storage lighting, it’s important to understand the distinct challenges that these environments present. Cold storage facilities, such as refrigerated warehouses, cold rooms, and freezers, operate at temperatures ranging from -20°F to 45°F (-28°C to 7°C). These extreme conditions can wreak havoc on traditional lighting solutions, leading to a host of problems:

- Reduced Illumination: Conventional light sources, such as fluorescent tubes, can see their light output decrease by up to 25% in cold temperatures, resulting in dimmer, less effective illumination.

- Shorter Lifespan: The harsh environment can cause traditional bulbs to fail prematurely, leading to more frequent replacements and higher maintenance costs.

- Safety Concerns: Poor lighting can contribute to workplace accidents, particularly in already hazardous cold storage areas where workers are handling heavy equipment and products.

- Energy Inefficiency: Conventional lighting solutions often consume more energy to compensate for their reduced performance in cold environments, driving up electricity costs.

By understanding these challenges, you can better appreciate the importance of investing in purpose-built cold storage lighting solutions that are designed to thrive in these demanding conditions.

The Power of LED Lighting in Cold Storage Applications

When it comes to cold storage lighting, LED (Light Emitting Diode) technology has emerged as the clear winner, offering a range of compelling advantages over traditional options. Here’s why LEDs are the smart choice for your cold storage facility:

1. Unmatched Energy Efficiency:

LEDs consume 60-65% less electricity than traditional bulbs, resulting in significant cost savings.

2. Instant, Full Brightness:

LEDs provide full brightness the moment they’re turned on, ensuring immediate visibility for workers.

3. Extended lifespan:

With a lifespan of up to 100,000 hours, LEDs greatly reduce maintenance and replacement costs.

4. Cold temperature performance:

LEDs maintain consistent, bright output even in sub-zero conditions, enhancing safety and productivity.

5. Enhanced visibility:

The crisp illumination of LEDs improves product visibility for easier labeling, inspection, and proper storage.

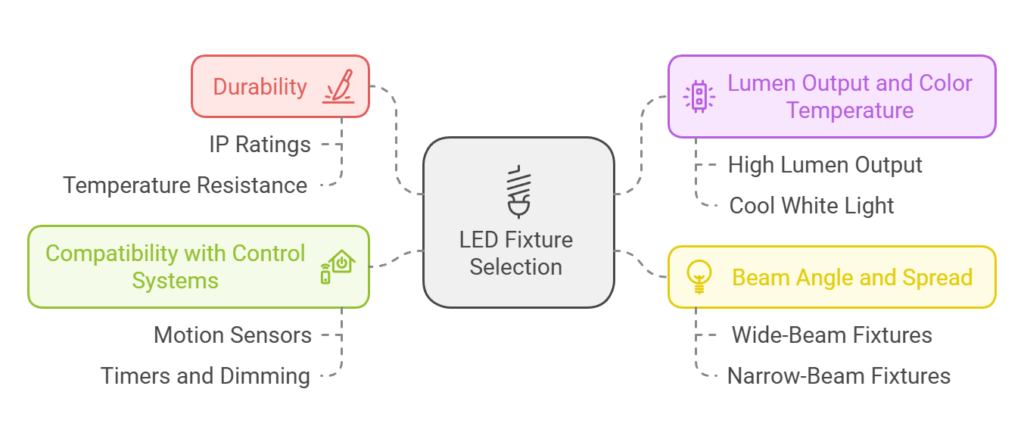

Choosing the Right Cold Storage Lighting Solutions

Now that we’ve established the superiority of LED lighting for cold storage applications, let’s explore some key factors to consider when selecting the perfect fixtures for your facility:

1. Fixture Durability:

Choose fixtures with high IP ratings (IP65+) to withstand moisture, condensation, and extreme temperatures.

2. Lumen Output and Color Temperature

Opt for high lumen output (10,000-15,000 lumens) and a cool white light (5000K-6000K) is generally recommended for cold storage applications, as it promotes alertness and visual acuity.

3. Beam Angle and Spread

Use wide-beam fixtures (120°+) for general lighting and narrow-beam options (60° or less) for task-specific areas. Combine strategically for uniform illumination.

4. Compatibility with Control Systems

Integrate LED fixtures with advanced lighting control systems (motion sensors, timers, dimming) to automate lighting, optimize energy usage, and create an efficient setup.

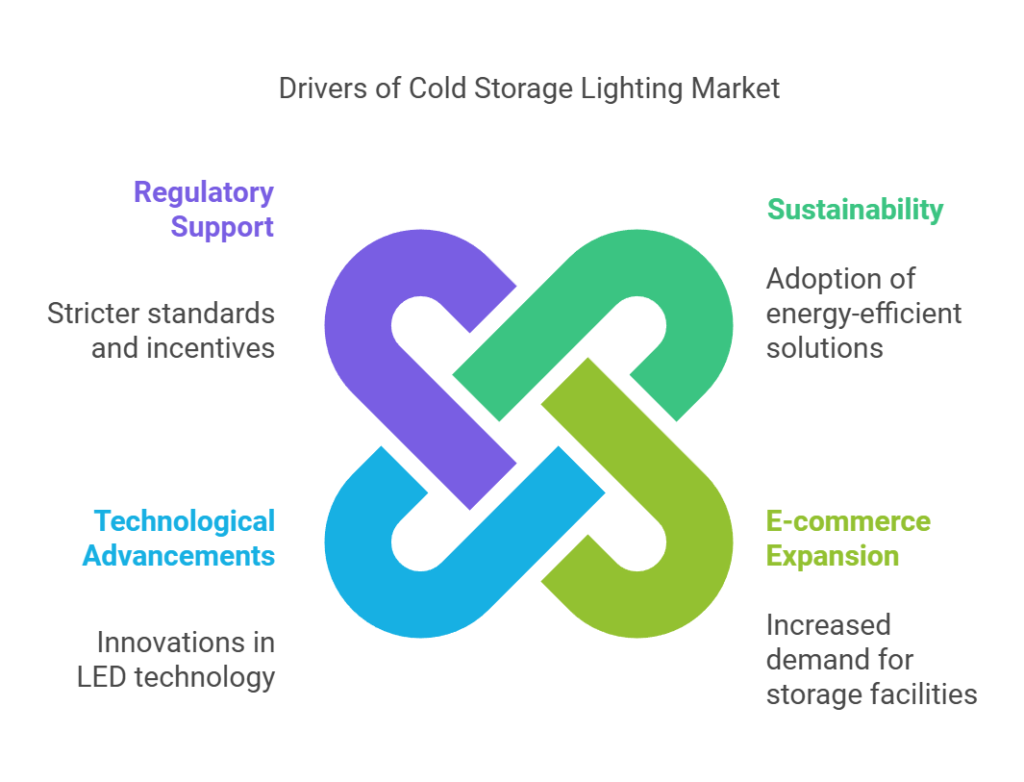

The Cold Storage Lighting Market: Trends and Projections

The global cold storage lighting market is poised for significant growth in the coming years, driven by the increasing demand for energy-efficient solutions and the rapid expansion of cold chain infrastructure worldwide. Industry experts predict that the market will reach a value of USD 2.5 billion by 2030, with a remarkable CAGR of 13% from 2023 to 2030.

This growth can be attributed to several key factors:

- Increasing Focus on Sustainability: As businesses seek to reduce their carbon footprint and energy costs, the adoption of energy-efficient LED lighting solutions is expected to accelerate in the cold storage sector.

- Rapid Expansion of E-commerce: The boom in online shopping has fueled the growth of cold storage facilities, particularly for perishable goods and pharmaceuticals, driving demand for specialized lighting solutions.

- Technological Advancements: Ongoing innovations in LED technology, such as higher lumen output, improved color rendering, and smart control systems, are making cold storage lighting even more appealing and cost-effective.

- Regulatory Support: Governments worldwide are implementing stricter energy efficiency standards and offering incentives for businesses to adopt sustainable lighting solutions, further propelling the market growth.

As the cold storage lighting market continues to expand, businesses that invest in cutting-edge LED solutions will be well-positioned to capitalize on these trends, improve their operational efficiency, and stay ahead of the competition.

Frequently Asked Questions About Cold Storage Lighting

To help you better understand the world of cold storage lighting, we’ve compiled a list of frequently asked questions and their answers:

1. What is cold storage lighting, and why is it important?

Cold storage lighting refers to specialized lighting solutions designed to operate efficiently and reliably in low-temperature environments, such as refrigerated warehouses, cold rooms, and freezers. Proper lighting is crucial in these settings to ensure worker safety, product visibility, and operational efficiency.

2. Why are LED lights the preferred choice for cold storage applications?

LED lights are the preferred choice for cold storage environments due to their numerous advantages, including exceptional energy efficiency, instant full brightness, longer lifespan, lower maintenance requirements, and superior performance in cold temperatures.

3. How much energy can I save by switching to LED lighting in my cold storage facility?

By upgrading to LED lighting, you can expect to reduce your energy consumption by 60-65% compared to traditional lighting solutions like fluorescent or incandescent bulbs. This translates into significant cost savings over the lifetime of the fixtures.

4. What should I look for when choosing LED fixtures for my cold storage application?

When selecting LED fixtures for your cold storage facility, consider factors such as fixture durability (IP rating), lumen output, color temperature, beam angle and spread, and compatibility with control systems. Choosing fixtures that are specifically designed for cold storage environments will ensure optimal performance and reliability.

5. How long do LED lights typically last in cold storage environments?

LED lights boast an impressive lifespan of up to 100,000 hours, which equates to more than 11 years of continuous operation. This extended lifespan significantly reduces the frequency of replacements and associated maintenance costs compared to traditional lighting solutions.

6. Can I integrate my cold storage LED lighting with advanced control systems?

Yes, many LED fixtures are compatible with advanced lighting control systems, allowing you to automate your lighting based on occupancy, schedules, or real-time data from sensors. This integration can further optimize your energy consumption and create a more efficient, responsive lighting setup.

7. What are the key trends driving the growth of the cold storage lighting market?

The cold storage lighting market is experiencing significant growth due to factors such as the increasing focus on sustainability, the rapid expansion of e-commerce, ongoing technological advancements in LED technology, and supportive government regulations and incentives.

Illuminating Your Path to Cold Storage Success

In the demanding world of cold storage, where efficiency, safety, and reliability are paramount, LED lighting stands out as the optimal solution. By upgrading to purpose-built LED fixtures, you can transform your cold storage operations, creating a brighter, safer, and more productive environment for your workers while significantly reducing your energy costs and maintenance burdens.

So, whether you’re managing a small cold room or a sprawling refrigerated warehouse, the time to act is now. By partnering with a trusted provider of cutting-edge cold storage lighting solutions, you can unlock the full potential of your facility, drive down costs, and set your business on a path to enduring growth and prosperity.

Don’t let the challenges of cold storage environments keep you in the dark. Embrace the power of LED lighting and watch as your operations thrive in a brighter, more efficient future. The transformation starts today – are you ready to take the leap?

If you’re ready to revolutionize your cold storage operations with state-of-the-art LED lighting solutions, our team at GERIPOO is here to guide you every step of the way. With years of experience and a deep commitment to customer success, we’ll work closely with you to design a customized lighting setup that meets your unique needs and exceeds your expectations.

Contact us today to schedule a consultation and discover how we can illuminate your path to cold storage success.