In the unforgiving world of cold storage facilities, where subzero temperatures and harsh conditions reign supreme, lighting plays a critical role in ensuring smooth operations, worker safety, and product integrity. But not just any lighting will do. Enter cold storage lighting—the unsung hero that illuminates the path to success in these frigid environments.

Cold storage lighting is a specialized category of lighting solutions designed to withstand the unique challenges posed by low-temperature settings, such as freezers and refrigerated warehouses. By providing reliable, energy-efficient illumination in these demanding conditions, cold storage lighting enhances visibility, improves safety, and ultimately contributes to the overall operational excellence of the facility.

In this comprehensive guide, we’ll delve into the key advantages of cold storage lighting, explore the different types of solutions available, and provide actionable insights to help you make informed decisions when selecting and implementing lighting for your cold storage environment.

How Does Cold Storage Lighting Enhance Energy Efficiency and Cost Savings?

One of the most compelling advantages of modern cold storage lighting solutions, particularly those utilizing LED technology, is their exceptional energy efficiency. LED lighting consumes up to 75% less energy compared to traditional options like fluorescent or incandescent bulbs. This significant reduction in energy consumption translates directly into substantial cost savings for facility owners and operators.

Consider this: a typical cold storage facility operating 24/7 with traditional lighting can spend thousands of dollars per month on electricity costs. By upgrading to LED cold storage lighting, the same facility can potentially slash its lighting-related energy expenses by 60-65%. Over the course of a year, these savings can add up to a considerable amount, positively impacting the bottom line.

| Lighting Type | Energy Consumption | Potential Annual Savings |

|---|---|---|

| Traditional (Fluorescent/Incandescent) | 100% | – |

| LED Cold Storage Lighting | 25-40% | 60-65% |

Moreover, the long lifespan of LED cold storage lighting further contributes to cost savings by reducing maintenance and replacement expenses. With an average lifespan of 50,000 to 100,000 hours, LED fixtures can last 2-5 times longer than traditional alternatives, minimizing disruptions and labor costs associated with frequent replacements.

What Role Does Cold Storage Lighting Play in Enhancing Safety and Visibility?

In the harsh, low-temperature environments of cold storage facilities, proper lighting is crucial for maintaining a safe and productive workspace. Poor visibility can lead to accidents, injuries, and costly errors that compromise both worker well-being and operational efficiency. This is where specialized cold storage lighting solutions come into play.

LED cold storage lighting is designed to provide bright, uniform illumination that enhances visibility in these challenging settings. With their instant-on capability and superior color rendering, LED fixtures ensure that workers can clearly see their surroundings, reducing the risk of slips, trips, and other accidents. Improved visibility also enables more accurate product identification and inventory management, minimizing errors and boosting overall productivity.

“Adequate lighting is essential for creating a safe and efficient work environment in cold storage facilities. LED cold storage lighting solutions provide the visibility needed to navigate these challenging spaces with confidence.” – Sarah Johnson, Occupational Safety Expert

Furthermore, cold storage lighting can be strategically placed to eliminate shadows and dark spots, ensuring that every corner of the facility is well-lit and easily navigable. By creating a brighter, more visually comfortable environment, cold storage lighting not only enhances safety but also improves employee morale and job satisfaction.

How Do Different Types of Cold Storage Lighting Solutions Compare?

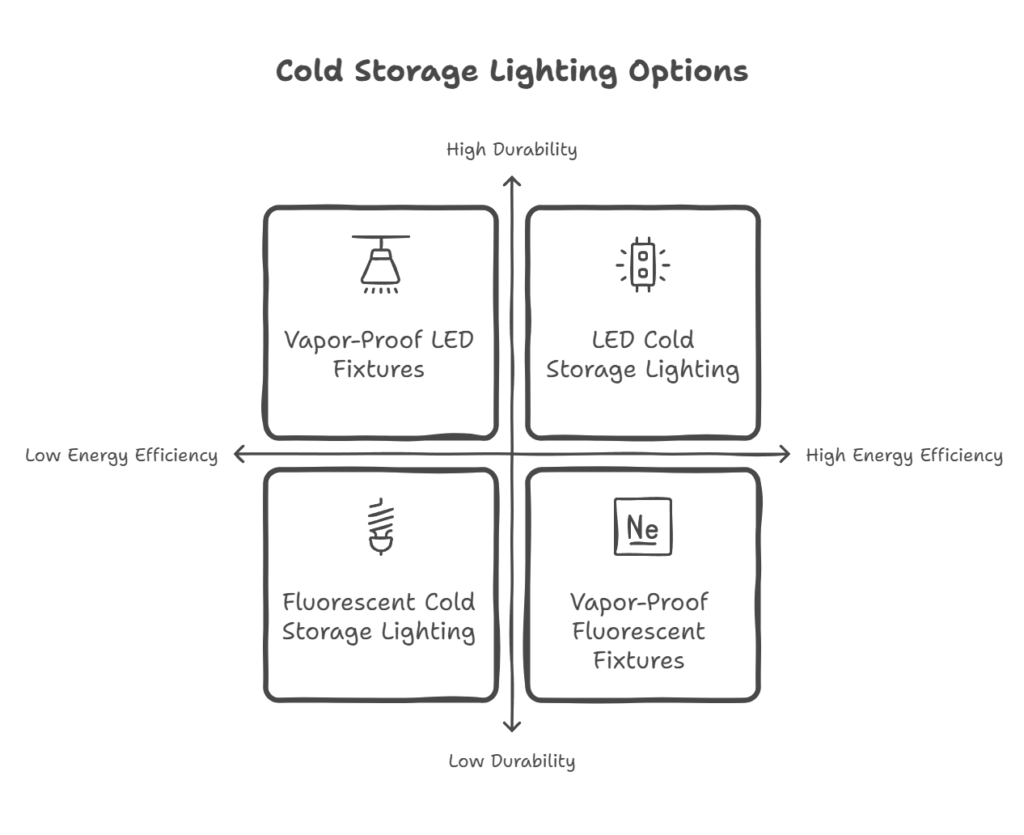

When it comes to selecting the right cold storage lighting solution for your facility, it’s essential to understand the different types of fixtures available and their unique characteristics. Let’s explore some of the most common options:

- LED Cold Storage Lighting: LED fixtures are the most energy-efficient and long-lasting option, offering bright, uniform illumination and excellent color rendering. They generate minimal heat and are resistant to moisture and condensation, making them ideal for low-temperature environments.

- Fluorescent Cold Storage Lighting: Fluorescent fixtures, while more efficient than incandescent bulbs, are less energy-efficient and have a shorter lifespan compared to LEDs. They can also be affected by low temperatures, resulting in reduced light output and potential flickering.

- Vapor-Proof Fixtures: Vapor-proof fixtures, available in both LED and fluorescent options, are specifically designed for wet and damp locations. They feature sealed housings that protect the internal components from moisture, condensation, and temperature fluctuations, making them suitable for cold storage applications.

When selecting a cold storage lighting solution, consider factors such as energy efficiency, lifespan, light output, color rendering, and suitability for low-temperature environments. Additionally, evaluate the specific needs of your facility, including the size of the space, required illumination levels, and any industry-specific regulations or standards that must be met.

What Are the Best Practices for Designing and Maintaining Cold Storage Lighting Systems?

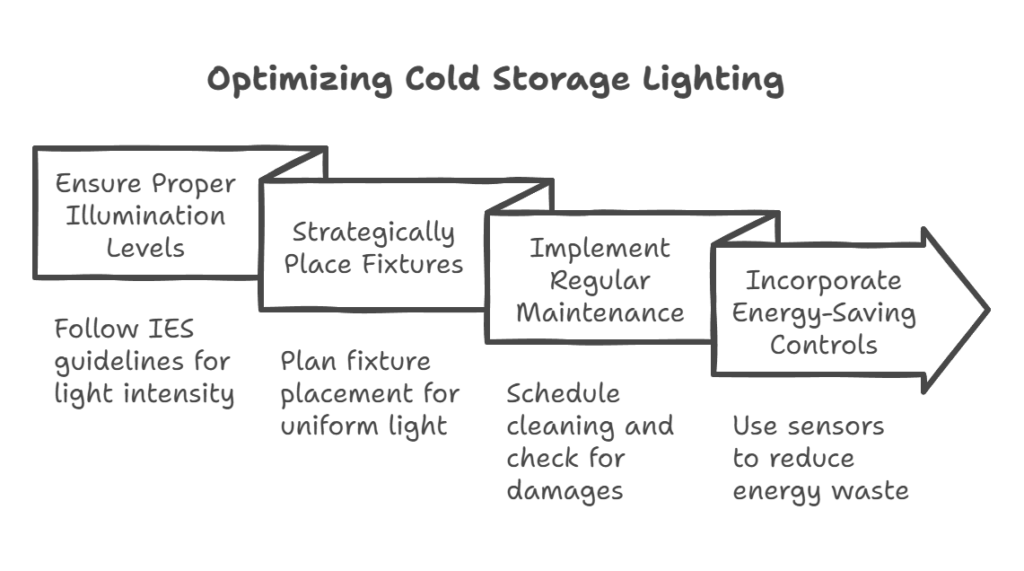

To maximize the benefits of cold storage lighting, it’s crucial to follow best practices in both the design and maintenance of your lighting system. Here are some key considerations:

- Proper Illumination Levels: Ensure that your cold storage lighting provides the recommended illumination levels for your specific application. The Illuminating Engineering Society (IES) offers guidelines for various cold storage environments, ranging from 20 to 100 foot-candles (fc) depending on the task and area.

- Strategic Fixture Placement: Carefully plan the placement of your cold storage lighting fixtures to achieve uniform illumination and minimize shadows. Consider factors such as shelf heights, aisle widths, and the overall layout of your facility to optimize light distribution.

- Regular Maintenance: Implement a regular maintenance schedule to keep your cold storage lighting system functioning at its best. This includes cleaning fixtures to remove dust and condensation, checking for any damage or malfunctions, and promptly replacing any burned-out bulbs or faulty components.

- Energy-Saving Controls: Incorporate energy-saving controls, such as occupancy sensors or dimmers, to further optimize the efficiency of your cold storage lighting. These controls can automatically adjust light levels based on activity or time of day, reducing energy waste and extending the lifespan of your fixtures.

By adhering to these best practices, you can ensure that your cold storage lighting system delivers optimal performance, energy efficiency, and safety for your facility.

How Can You Select the Right Cold Storage Lighting Solution for Your Facility?

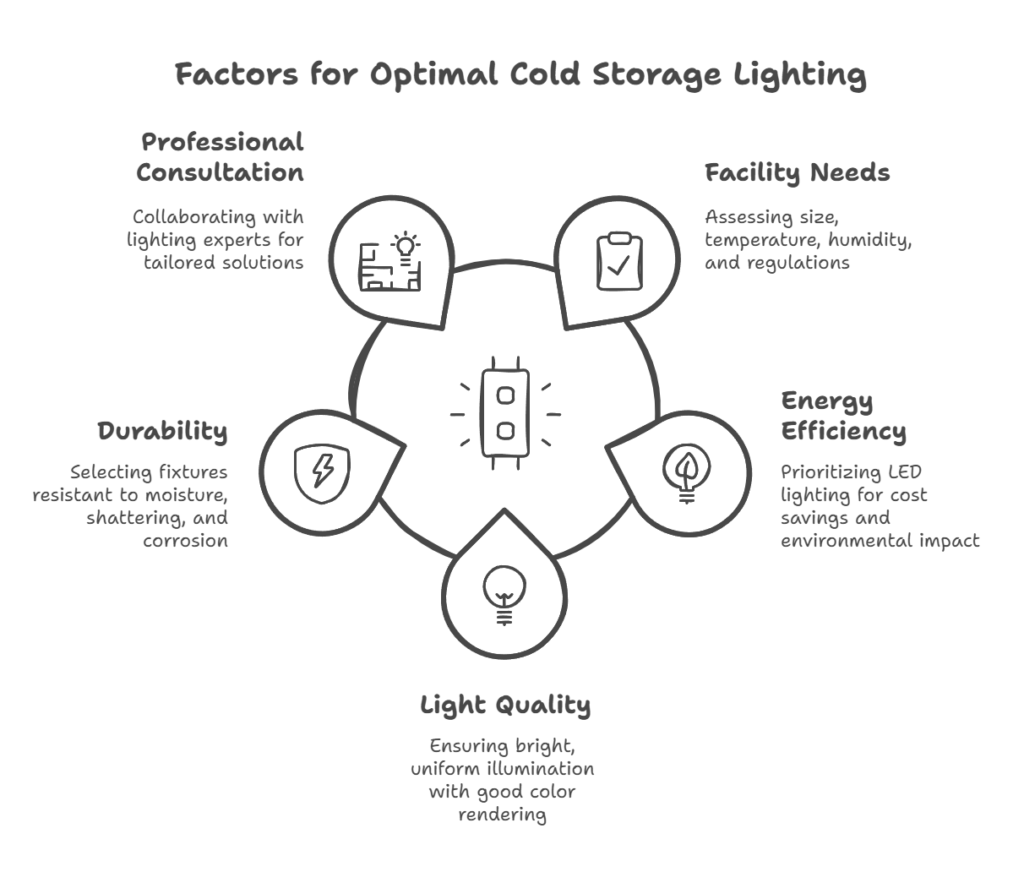

Choosing the right cold storage lighting solution for your facility involves careful consideration of several key factors. To make an informed decision, follow these steps:

- Assess Your Facility’s Needs: Evaluate the specific requirements of your cold storage environment, including the size of the space, temperature range, humidity levels, and any industry-specific regulations or standards that must be met.

- Consider Energy Efficiency: Prioritize energy-efficient options, such as LED cold storage lighting, to maximize cost savings and minimize your facility’s environmental impact.

- Evaluate Light Quality and Distribution: Select fixtures that provide bright, uniform illumination with good color rendering to enhance visibility and safety throughout your facility.

- Look for Durability and Reliability: Choose cold storage lighting solutions that are built to withstand the harsh conditions of low-temperature environments, with features such as moisture resistance, shatterproof lenses, and corrosion-resistant materials.

- Consult with Lighting Professionals: Work with experienced lighting professionals or manufacturers who specialize in cold storage applications. They can provide valuable guidance and recommendations based on your specific needs and help you select the most suitable solutions for your facility.

By following these steps and carefully evaluating your options, you can ensure that you select a cold storage lighting solution that delivers optimal performance, energy efficiency, and long-term value for your facility.

In the demanding world of cold storage, where every detail matters, lighting plays a crucial role in ensuring operational excellence. By harnessing the power of specialized cold storage lighting solutions, you can create a safer, more efficient, and more productive environment for your facility and your team.

Whether you’re looking to upgrade your existing lighting system or designing a new cold storage facility from the ground up, understanding the key advantages, types, and best practices of cold storage lighting is essential. By making informed decisions and investing in the right solutions, you can illuminate the path to success in even the coldest, harshest conditions.

So, embrace the power of cold storage lighting and watch as your facility thrives in the face of any challenge. With the right lighting by your side, you’ll be ready to take on the cold and come out on top, every time.